EOT CRANES

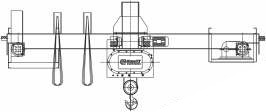

SINGLE GIRDER EOT CRANES

Span

3 mtrs. to 35 mtrs.

Safe Working Load

500 kgs. to

20,000 kgs.

Crane Control

From floor through Pendant Push Buttons, Optionally Through Radio

Remote Control / cabin with master control.

Motors

Squirrel Cage & Slip Motors based on application requirements, built-in

separator electrically operated fail to safe brakes for all three motions.

Motors with ‘F’ class insulation provided in all motions.

Power Supply System

To Hoist and Cross Travel through Trailing Cables / Drag Chain to Crane

through Shrouded Bus Bars / Trailing Cable / MS Angle Iron Conductors /

Bare Copper Conductors (depending on customer’s choice and application).

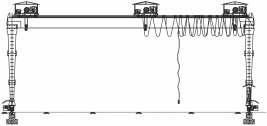

DOUBLE GIRDER EOT CRANES

Span

5 mtrs. to 40 mtrs.

Safe Working Load

500 kgs. to

2,00,000 kgs.

Class of Duty/Standards

Equivalent to M3, M5, M7, M8 as per IS:3177 / IS:807

Drive System

Accordance with IS : 3177 Structural Parts With IS : 807

and Other Miscellaneous Parts with IS : 3177, IS : 3938

and IS:4137

Speeds

Selected depending on client specifications/application/

shed dimensions

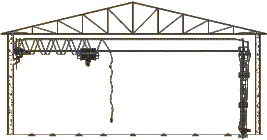

GOLIATH CRANES

SEMI GOLIATH CRANES

Span

5 mtrs. to 20 mtrs.

Safe Working Load

1000 kgs. to

60,000 kgs.

Crane Control

From floor through Pendant Push Buttons, Optionally Through Radio

Remote Control / cabin with master control.

Motors

Squirrel Cage & Slip Motors based on application requirements, built-in

separator electrically operated fail to safe brakes for all three motions.

Motors with ‘F’ class insulation provided in all motions.

Power Supply System

To Hoist and Cross Travel through Trailing Cables / Drag Chain to Crane

through Shrouded Bus Bars / Trailing Cable / MS Angle Iron Conductors /

Bare Copper Conductors (depending on customer’s choice and application).

GOLIATH CRANES

Span

5 mtrs. to 50 mtrs.

Safe Working Load

1000 kgs. to

1,00,000 kgs.

Class of Duty/Standards

Equivalent to M3, M5, M7, M8 as per IS:3177 / IS:807

Drive System

Accordance with IS : 3177 Structural Parts With IS : 807

and Other Miscellaneous Parts with IS : 3177, IS : 3938

and IS:4137

Speeds

Selected depending on client specifications/application/

shed dimensions

Selected depending

JIB CRANES

JIB CRANES SPECIFICATION

Span

2 mtrs. to 7 mtrs.

Safe working load

250 kgs. to 5,000 kgs.

Crane Control

From floor through Pendant Push Buttons, Optionally Through Radio Remote

Control / cabin with master control.

Motors

Squirrel Cage, based on application requirements, built-in separator

electrically operated fail to safe brakes for all three motions. Motors with

‘F’ class insulation provided in all motions.

Power Supply System

To Hoist and Cross Travel through Trailing Cables / Drag Chain

(depending on customer’s choice and application).

Drive System

Accordance with IS : 3177 Structural Parts With IS : 807 and Other

Miscellaneous Parts with IS : 3177, IS : 3938 and IS:4137

Speeds

Selected depending on client specifications/application/ shed dimensions

Class of Duty/Standards

Equivalent to M3, M5, M7, M8

as per IS:3177 / IS:807

CAGE HOIST ARRANGEMENT

FLAME PROOF / NON FLAME PROOF

Ground level + 10

Pay Load Capacity500 kgs. to 5,000 kgs.

The floor doors are provided with mechanical and electrical locking arrangement. Hence unless floor door is closed properly, lift cannot be started. additional gravity limit switch is provided for extra safety. In case of failure of over hoisting limit switch, power will be cut off by gravity limit switch upon over traveling of the cage. Every single rope is having rated capacity with min. 6 F.S. which in four fall construction will provide four times the required F.S. Hence even in case of breakage of 3 wire ropes out of 4. the cage will not fall. This is extra safety over any other conventional similar type goods lift The cage is made of rolled steel sections and sides are covered with bumped sheets. Cage top is covered with M.S. Sheets and bottom is covered with chequered plate for antiskid property. Collapsible doors are provided on cage as per entry and exit position. The cage is being guided with rollers on “T” guide rail. Antifriction bearings are provided for smooth and efficient traveling with low friction and longer life.

HOISTS

FLAME PROOF HOISTS

Class of Duty /Standards

IS : 3938 and IS : 2148

Safe Working Load

250 kgs. to

25,000 kgs.

KaneXT flame proof hoists are offered for gas group I, IIA and IIB

sutable for zone-1 and zone-2 areas whereas for gas group IIC

flame proof hoists are offered only for zone-2 areas.

KaneXT flame proof hoists are designed in modular construction

which greatly simplifies repairs and cuts down time. KaneXT flame

proof hoists are designed in accordance with IS-3938. All electrical

apparatus are housed in flame proof enclosures confirming to

IS - 2148 and mechanical components are designed so that there is

no ferrous metal to ferrous metal contact in order to avoid any

chance of sparkling. Hence KaneXT flame proof

hoists are flame proof as well as spark proof.

FOR THE FASTGROWING COMPANIES

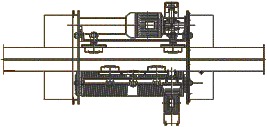

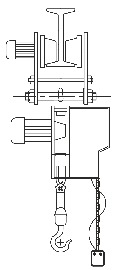

WIRE ROPE HOISTS

Safe Working Load

500 kgs. to

25,000 kgs.

Crane Control

From floor through Pendant Push Buttons, Optionally

Through Radio Remote Control.

Motors

Squirrel Cage & Slip Ring Motors based on application requirements, built-in separator electrically operated fail to safe brakes for all three motions.

Motors with ‘F’ class insulation provided in all motions.

Power Supply System

To Hoist and Cross Travel through Trailing Cables / Shrouded type DSL

System (depending on customer’s choice and application).

Drive System

Drive through Squirrel Cage Induction Geared Motors

with Built-in fail to safe brakes.

Speeds

Selected depending on client specifications /applications / shed dimensions

Class of Duty / Standards

Equivalent to IS 3938

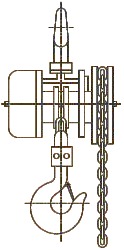

CHAIN HOISTS

CHAIN HOISTS

Safe Working Load

500 kgs. to 2,000 kgs.

Concentrated design for high substance.

Quality Designed forged steel top and bottom hooks.

Precision shaped load sheave is mounted to assure

minimal wear and smooth operation.

CHAIN PULLEY BLOCKS

CHAIN PULLEY BLOCKS

Safe Working Load

Capacity upto 20 Tons.

Low Headroom.

Positive Transmission

(Bearing Supporter).

Lubrication :

Totally enclosed gear case is

packed with sufficient grease.

CRANE SPARES & SERVICES